Among the many advantages that classic injection moulding technology offers for producing light guides, there is one main disadvantage in some scenarios: the design and construction of the required tools takes time and requires a substantial initial investment. Therefore this kind of tool-based technology is often not the most cost-effective alternative for projects with smaller quantities.

M-Cut 2D light guide: ideal for medium quantities

Versatile. Fast. Cost-effective. The main idea behind M-Cut light guide technology is to create fast, easy, cost-effective individual light guide solutions, even for small quantities. It uses precisely processed, homogeneous PMMA sheets that are fully transparent or contain diffuser particles, depending on the requirements in question.

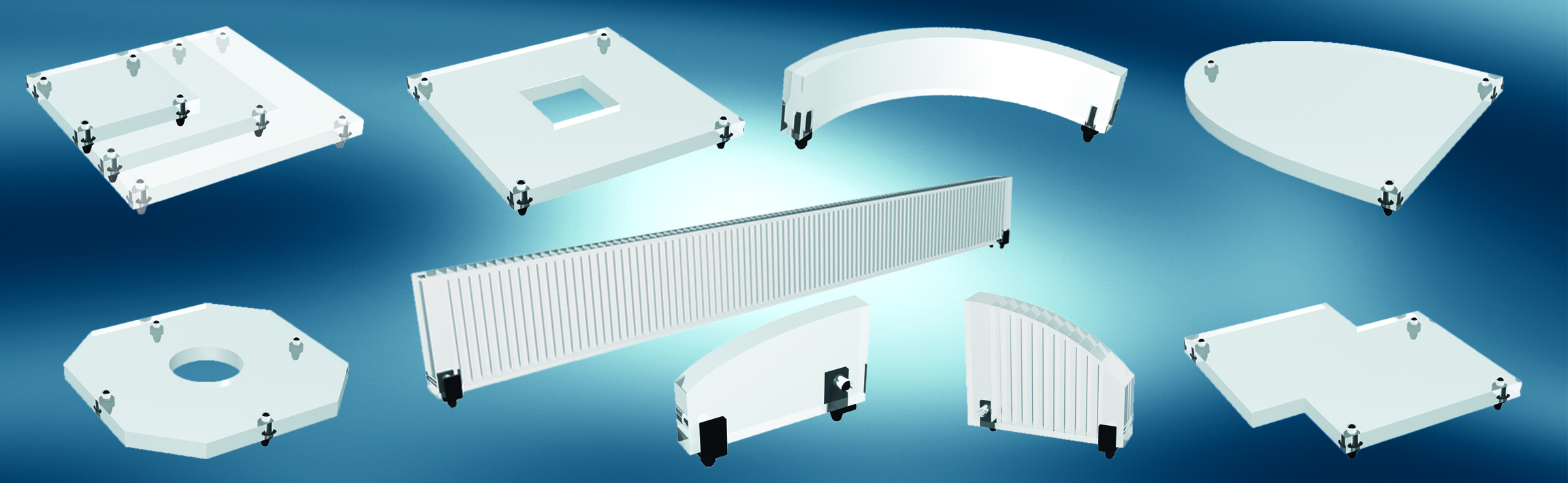

M-Cut has three different basic types – the surface light guide, bar graph light guide and solid strip light guide. These allow high-quality, customised background lighting to be implemented for logos, graphics or information boards, as well as individual multi-displays or homogeneous line and lettering backlighting. Two of the three light guide dimensions can be custom-designed, opening up a whole range of possibilities. Contour-tracking light guides are possible, for example under a curved housing cover, as well as up to 100x bar graph displays or surface light guides with individual 2D free-form contours.

In M-Cut solutions, the light is fed into the light guides from the side as a rule. Deliberate interruptions in the PMMA sheet, developed using lighting technology, ensure light is distributed homogeneously as desired on the front of the light guide (axial emission). The inclusion of microstructures, laser engraving or additive reflective coatings allows the light to be emitted in a specific pattern on the sides (lateral emission).

Customer projects with M-Cut technology

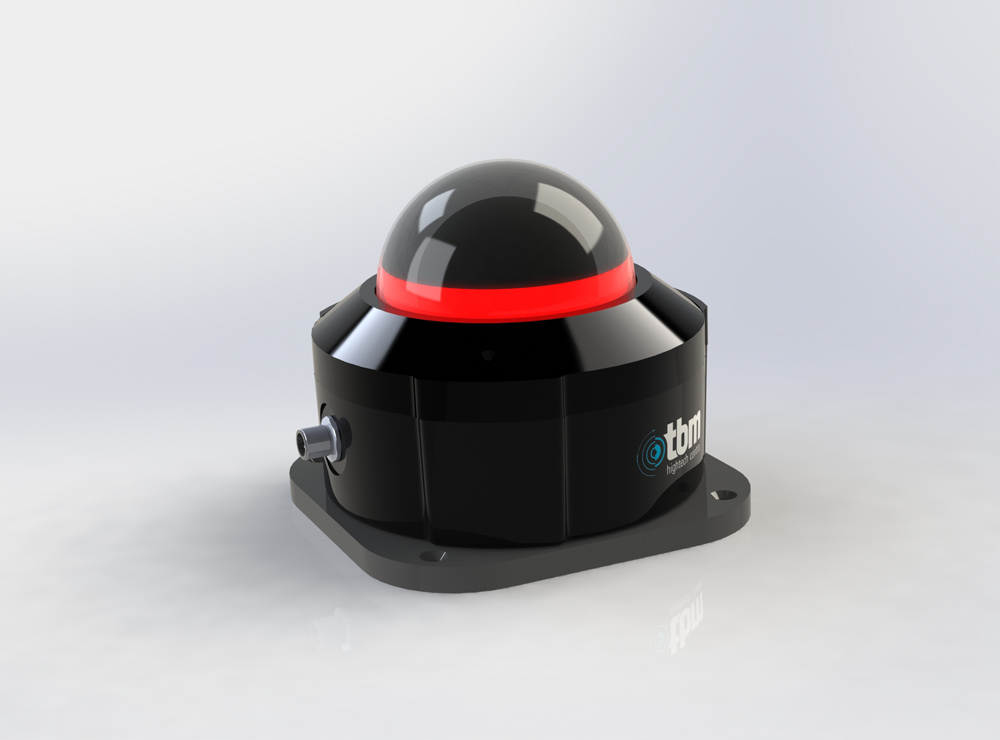

Our M-Cut 2D light guide technology has been used in a wide range of projects, because it offers flexibility and versatility. Examples are applications by our customers Geberit, Clage, UNITRO-Fleischmann and tbm hightech control. For more information on these and many other projects, visit our Reference page.

Strengths, limits and alternatives

M-Cut is a form of light guide technology whose advantages are as varied as they are useful: its incredible versatility offers ample freedom to design devices individually, and the tool-free manufacturing method means products can be made quickly and easily with no need for an upfront investment in tools. The only initial costs are for development, a lighting evaluation (if applicable) and manufacturing equipment.

M-Cut technology has its limits in the light guide’s third dimension, which cannot be freely designed. If more complex geometries are required to achieve the desired lighting result, or if there is insufficient installation space in the right place, other technologies have an advantage. Solutions using plastic injection moulding may be more cost-effective in the long term for projects with large quantities, due to the lower unit costs and despite the initial investment in tools. Depending on the requirements of the particular customer application, other lighting solutions based on our M-Fibre side light fibre system or textile lighting systems are a good alternative too.