More light for logos, signs and text

Illuminated logos and signs are encountered with increasing frequency in modern products. At Mentor, the specialist in light guides, opto-electronic components and product-integrated lighting solutions, they are certain that this is not by chance. After all, light offers the widest range of possibilities to anyone who wants to, in the truest sense of the word, make a mark in their product design. Staging of the brand logo, communication of status information via coloured symbols and texts, or the integration of decorative graphics are examples of the functional and aesthetic added value that can be achieved with light in this way.

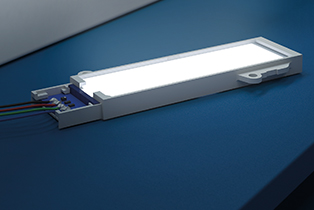

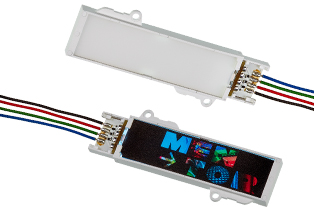

Now, a new LED module now makes it particularly easy to backlight logos, signs and lettering cost-effectively: as a standard product with short delivery times and low minimum order quantities or as a customised solution with a wide range of options. The new area light from Mentor is equipped with a colour RGB-LED, an integrated diffusor and stranded wire connection. It provides high-quality, homogeneous lighting for areas of up to 50 x 16 mm. For illustration and test purposes, a sample version, with a diffusor already printed, is available from stock.

Customized shapes, e.g. circle, ellipsis, triangle, sickle or freeform, are also possible as special sizes. The same applies to the option of an alternative LED, special PCB equipment, or different electrical connections. During development, particular value was placed on simple and industry-appropriate assembly. The compact design and very flat structure (just 5.5 mm) mean they can even be fitted in products with tight installation space.

A variety of mounting types and several alternative printing options make the area light module very flexible and ensure it can be used for a broad range of applications. When printing onto the diffusor, the desired symbol or lettering is applied to the front of the diffusor in such a way that light only shines through the desired areas. A transparent bezel is also required for flush closure of the front of the device. Rear printing directly on the bezel is also possible, as well as adding a bonded film. Another possibility is the use of translucent film, which is used as a final element on the front of the end system’s housing. Area lighting can also be used to illuminate a diffusing area, which has been produced through 2-component injection moulding in the front of the housing.

To ensure that designers and developers can use the LED module flexibly as a standard component, it has been designed in such a way that it can be integrated in housing fronts in a variety of ways. The housing features a variety of mounting options, namely mounting tabs, locking hooks, brackets or similar. The lighting module can be applied to the back of the housing of the final application through insertion, snap-fitting or press-in fitting. Subsequent joining procedures, such as heat staking, heat riveting or ultrasonic methods, are also possible, as well as bonding or screw connection.

Download Press Release

Your contact person