The ideas of lighting and interior designers in the automotive industry are presenting us with an endless series of new challenges – occasionally some that cannot be achieved with established technology. To satisfy these requirements, as well to create new opportunities to integrate light usefully into products, we are continually developing our technology portfolio. The latest examples of this are our textile lighting systems.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationTextile lighting systems: for seats, upholstered furniture and so much more

The textile material of the light guide, rather than its usage in textile applications, is what gives these products their name. Nevertheless, because of their extensive flexibility, textile lighting systems are perfect for integrating light into textiles – but can be used in other ways too. In addition to their use in textile end products, light-guiding fibre mats can also be used in non-textile end products. They can provide good solutions for complex installation space situations that cannot be implemented using other technologies.

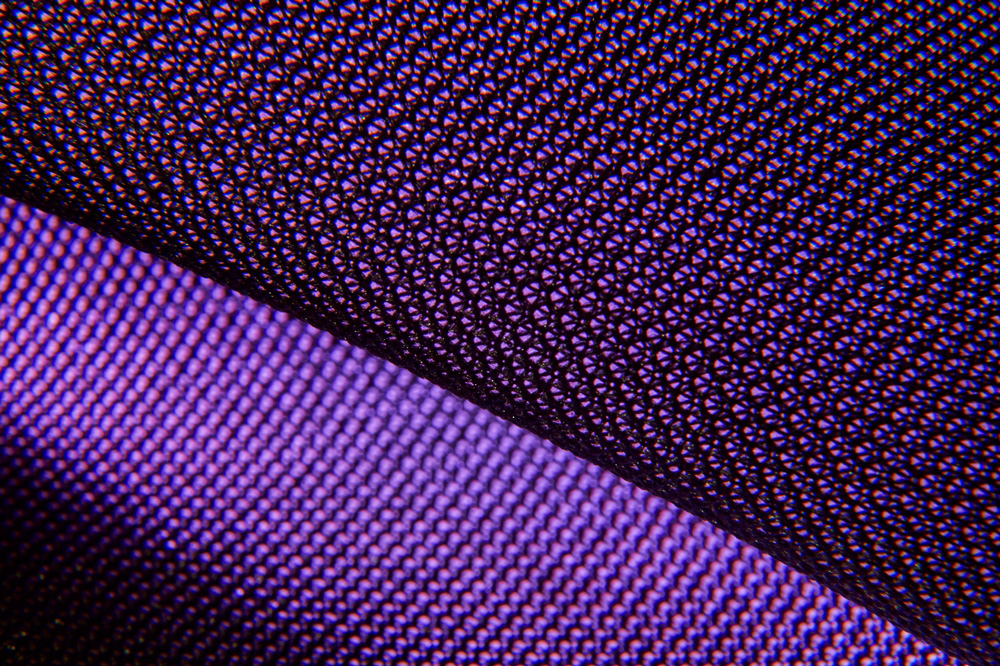

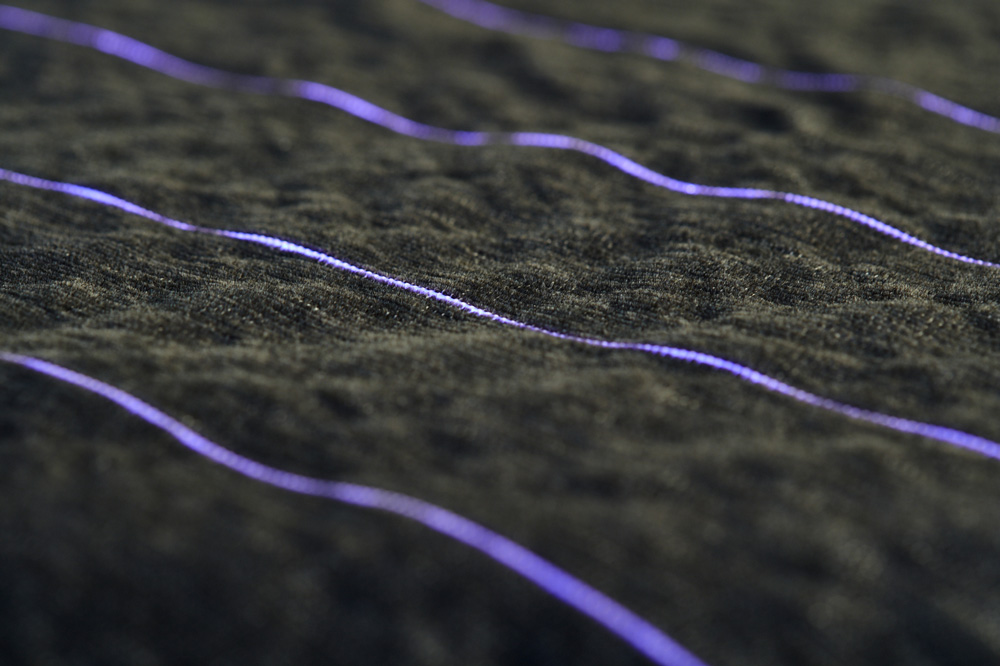

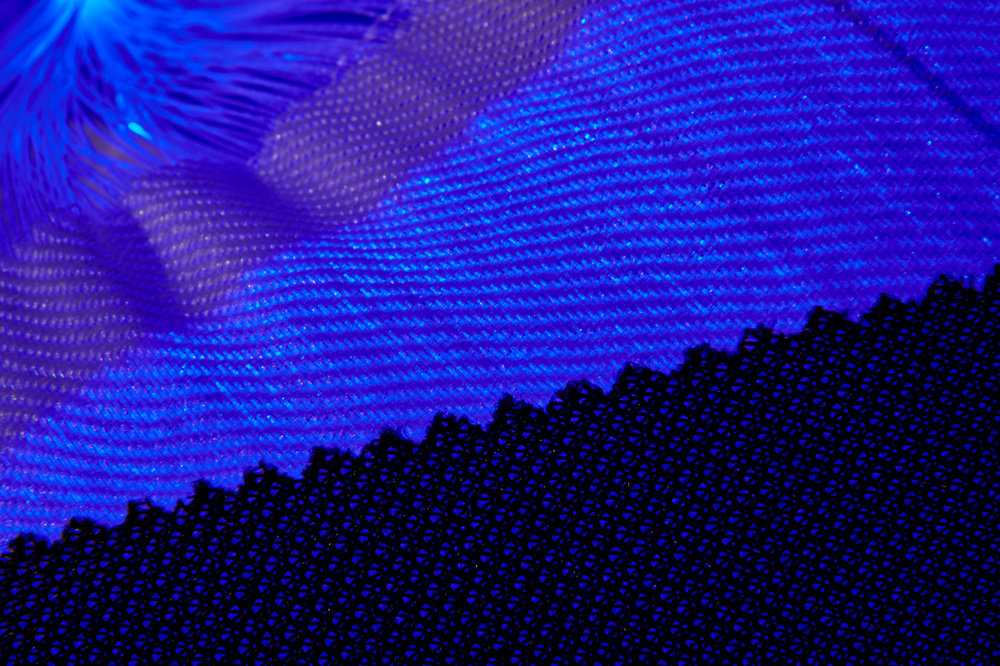

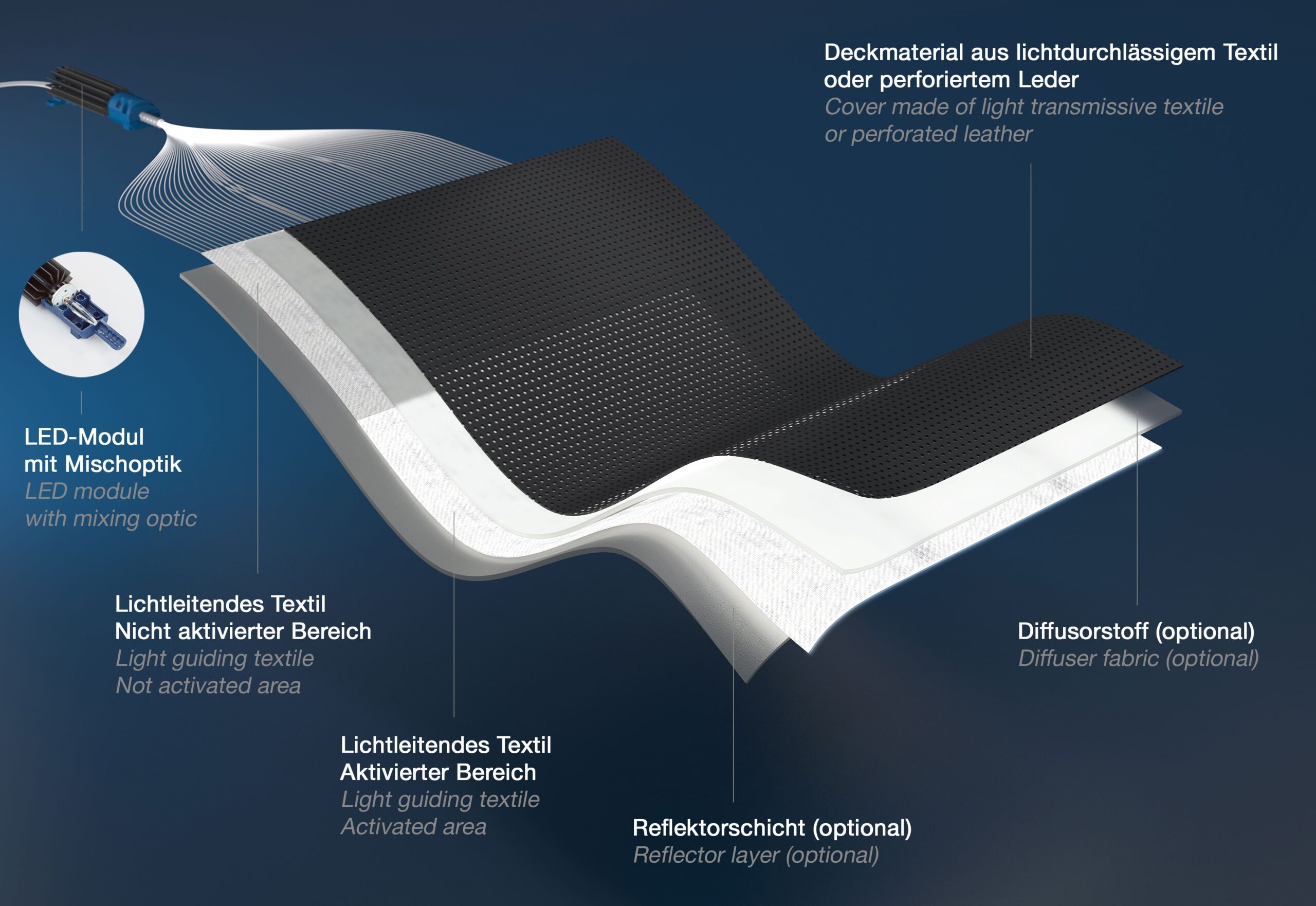

The basic components of textile lighting systems are at least one LED light source and a textile material – a fabric that acts as a light guide. The light is fed into the fabric’s fibre ends and can be emitted from its side (lateral emission). The fabric is provided with suitable light-scattering surface structures at the desired light output points for this purpose. However, the light can be emitted – additionally or exclusively – at the end of the fibres too (axial emission).

The fabric consists of clear plastic PMMA optical fibres (POFs), which are woven with warp threads made from white polyester to form light-guiding fibre mats. A diffusor and top fabric are placed over the light-conducting fibre mat and a reflector is placed under it. The individual POFs are combined together into one or more ferrules, and the ferrules are connected to the LED modules. A special mixer optic in the LED module ensures that the LED’s light is distributed optimally to all polished fibre ends in the ferrule.

Textile lighting systems are flexible and drapeable, i.e. spherically deformable. This is a key advantage for integrating the system into many different applications. Combined with the very flat structure of the overall design, this technology allows developers to work very flexibly where installation space is often tight. Another advantage: As the technology barely requires any component-specific tools, it enables short development times and is also suitable for quantities where a tool-based technology is not cost-effective.

Textile lighting solutions can be used in very versatile ways in vehicle interiors: they can illuminate and backlight textile and non-textile surfaces in door panels and seats, in the cockpit, footwells or boot – for decorative purposes, for branding using an illuminated logo or to provide safety or guide functions. Other exciting applications of textile lighting solutions are piping and edging lighting, light tracers in textiles and perforated leather backlighting. If multiple LED modules are used to feed in the light, impressive dynamic lighting scenarios are possible.

You can find more information on the MUNDA website.

other technologies

About MUNDA

MENTOR’s textile lighting solutions are developed at MUNDA. MUNDA Textile Lichtsysteme GmbH in Erkrath, Germany is a joint venture between MENTOR and the automotive textile specialist AUNDE. It combines AUNDE’s expertise in technical textiles and MENTOR’s experience in LED lighting technology. Armed with this know-how, MUNDA develops textile lighting solutions for both parent companies.

About AUNDE

Founded in Mönchengladbach, Germany in 1899, AUNDE, with its brands AUNDE, ISRINGHAUSEN and FEHRER, produces yarns, technical textiles, foams, seat covers, seats, technical springs and interior modules for leading automotive manufacturers worldwide. AUNDE has more than 24,500 employees and produces goods in 117 factories in 29 countries worldwide.